Glulam

Glulam is a high-quality material which is useful in a wide range of applications and possesses outstanding properties. It can be incorporated ideally in interior design and is particularly attractive.

Glulam – A high-tech product

The term glulam is understood to be components for wooden constructions that are made of technically dried spruce boards, from which flaws that reduce rigidity and visual defects such as large knots, pitch-pockets and ingrown bark have been removed. Elimination of the weak points and the layered structure result in the high-tech product known as glulam.

High dimensional stability

Normal construction timber continues to dry in its installation condition. It shrinks, distorts and warps. Solid wood 24 cm wide, for example, shrinks between 10 and 20 mm with a wood moisture content reduction from 30 % to 10 %. This can also result in the formation of cracks. The most frequent cause of leaks in external walls and the consequent damage caused by the moisture is the shrinking of timber that was installed when it was still too wet. During the manufacture of glulam, the lamellae are technically dried to approx. 12 % wood moisture content before gluing, and they are planed afterwards. The finished glulam thus already has a wood moisture content which corresponds to the equilibrium moisture in the installation condition.

Glulam exhibits substantially better characteristics than solid wood during processing. It will also not warp over the long term and the degree of cracking is minimized.Glulam is thus particularly suitable for visible components and the basis for a durable and dimensionally stable construction.

Large dimensions and slimmer cross sections:

Glulam exhibits a higher degree of stability and higher rigidity than normal timber. It can be manufactured in lengths up to 18 m and dimensions up to 240 x 1240 mm. It is therefore possible to produce slim, supporting framework systems that cover large spans without the need for supports.

High-quality surfaces

Planed and chamfered on all sides, glulam has a smooth and appealing surface.

In order to fulfil the most diverse creative requirements, glulam is also available in different surface qualities:

- Visual quality for components and all kinds of constructions with static and optical requirements

- Industrial quality for glulam with static requirements but without optical requirements

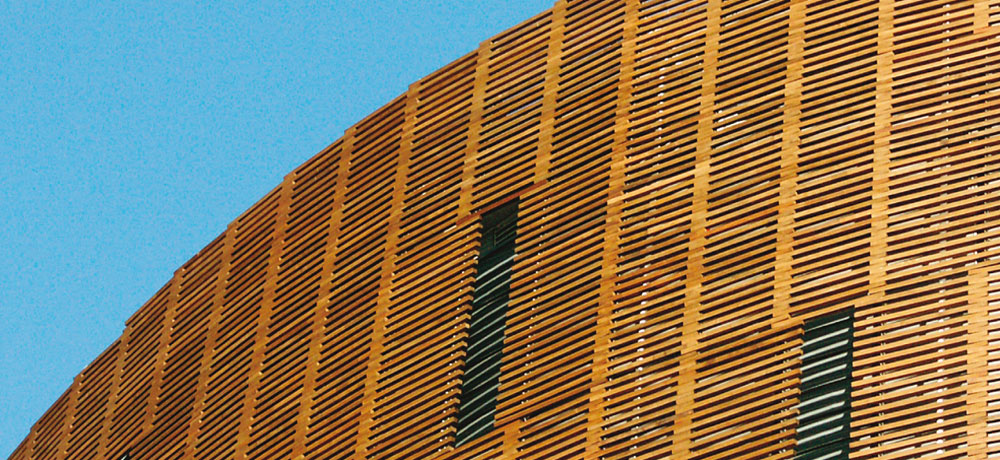

Attractive possibilities for interior design

The technical features mentioned also provide architectural and/or creative advantages. Glulam harmonizes perfectly with other materials such as natural stone, concrete, steel or glass. Additional design accents can be achieved through treatment with paint, waxes or glazes.

Simple and trouble-free processing

High-quality materialis also very valuable through its speed of processing.

No chemical wood preservation required indoors

Fungi that is destructive to timber requires wood moisture to grow - this can be eliminated with the professional installation of glulam under the roof and in the building interior. Therefore, in accordance with DIN 68800 part 3, chemical wood preservation is not required in virtually all cases.

Outstanding living biology characteristics

As a natural product, glulam has exceptional habitation biology characteristics and has a positive effect on the indoor climate.

Glulam from Mosser ... in proven quality

Glulam from Mosser is a trouble-free, versatile branded product, which is manufactured using state-of-the-art production technology. It goes without saying that Mosser has all of the relevant marks of conformity, which can be accessed in the Download Center.

Fire retarding qualities

In its use as a compact constructional element, wood possesses a high resistance to fire since it only chars on the outside; its internal structure is protected. The highest classes of fire protection can also be met with constructions made of wood. Due to its easily calculable fire behavior, wood is suitable for the most diverse construction projects when used professionally.

Although wood is considered a flammable construction material, the material properties in a fire are relatively favorable. Contrary to steel or concrete constructions, the time-based penetration of the fire inside the timber permits calculable fire-fighting operations since the remaining stability of the construction can be determined exactly.

Glulam is categorized as fire class D-s2-d0 in EN 14080:2013.

- Euro class D

- Smoke production s2

- Flaming droplets d0

The burn rate is regulated in Euro code 5 (ENV 1995-1-2) and set at 0.7 mm/min.

Precise – Fast – Safe

The high level of pre-fabrication for wood elements, roof and frame constructions make the realization of a construction possible a few days after planning is complete. On site, much lighter cranes are needed than on reinforced concrete sites. Moving and connecting components in wooden constructions is very quick and does not require any drying or hardening times. Today's joining technologies are high-tech, the precision is many times better than with reinforced concrete.

These advantages speak a clear language and will considerably increase the importance of engineered wood beyond home building to multi-floor homes and offices and up to high-quality hall construction.

After all, the lower weight of wood constructions offers enormous advantages in earthquake zones. This is amplified by the higher elasticity of the material and the joining elements used. Reinforced concrete is stiff and, if something breaks, it collapses quickly. Basically, building with wood is safe, precise and, above all, fast.

Weathering

If construction methods such as marquise, aluminum paneling on windows, etc are used to protect the wood completely from weather influences, then it can practically last forever. It is very important that water can not build up or condense in any part of the construction. The constructive wood protection is the most efficient measure that can be taken to extend considerably the life of the wood construction. If this is not possible, then suitable chemical measures are necessary to influence the lifespan of the wood. Chemical wood protection mainly concerns surface treatments with paint or stain to protect the wood from UV rays and any moisture. However, this requires regular treatment.

General description

Glulam consists of at least two boards or laminations that have been technically dried and glued together parallel to the fibers. Before gluing, the laminations are graded visually or mechanically by strength and planed. Mosser uses the most up-to-date scanner technology to grade glulam by strength and optical features to ensure the high standard of quality that has been maintained for over 25 years.

Classification

European standards define a variety of different strength classes. The Mosser standard is strength class GL 24c. This strength class is ideal for manufacture with the available raw materials and is, therefore, the most economical and visually pleasing classification.

GL 24h is also available on request for an additional charge. For constructions requiring more strength, we can also supply strength classes GL 28c (from 140/320 mm) and

GL 30h (from 120 mm) upon request for certain cross sections. Each support has clear identification on the front with all relevant information on quality, dimension, strength, length and date of manufacture.

Gluing (acc. to EN 301/302, MUF)

We use melamine urea resin glue to glue our glulam and glulam ceiling elements.

The glue is waterproof and weather-resistant and produces light glued joints, which do not darken over time. This gluing system is almost formaldehyde free – there are no increased levels of formaldehyde in completely hardened products in comparison to un-glued spruce wood.

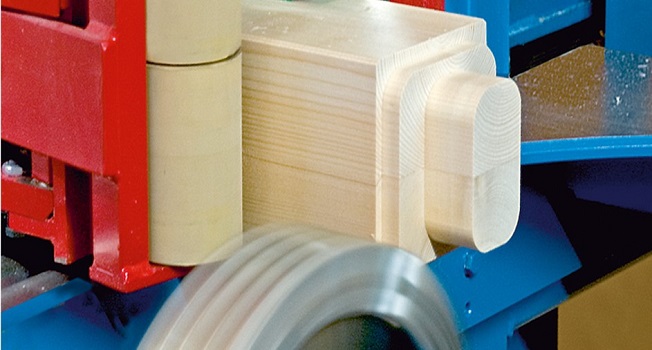

Joinery

Our modern joinery machine enables us to achieve precise processing of components and millimeter accuracy.

Our customers receive top-quality timber construction elements that are ready to install. This will enable you to calculate precisely and achieve high supply capability and optimized assembly times.

Please send your inquiries to us in .BVX or .BVN format.

Our sales team will be glad to assist you if you require any additional information on our products.