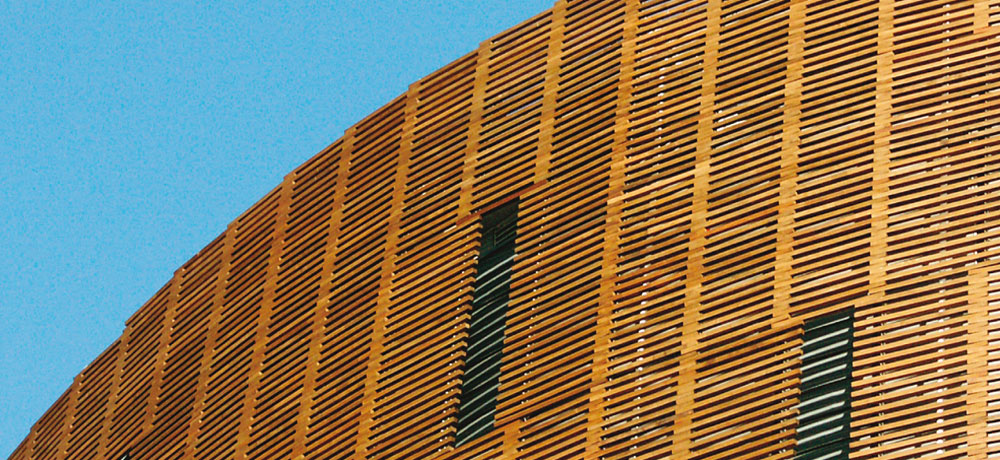

Sustainability at Mosser

Sustainability in practice

Here at Mosser, we tackle the challenges associated with sustainability, a key topic in current times, with company-wide measures, and in doing so, we create the foundation for a better tomorrow. We view the trend toward increased sustainability as an opportunity to promote early innovation and development.

Our company is of course PEFC-certified. We were the first Austrian timber processor to be awarded this certificate, which provides our customers with additional assurance that the timber in our products is sourced using sustainable forest management practices.

We have been determining key sustainability figures since 2020, which support us in reaching our strategic sustainability goals. We are therefore able to assess our contributions toward greater sustainability and document our progress. We view this as the basis for broadening our commitment to increased climate protection.

Since January 1, 2022, our production lines have been running exclusively using power from renewable sources:

- All the electricity we use comes from renewable sources and the vast majority is generated from hydropower.

- Thermal energy is also generated exclusively using sustainable biomass.

By adopting pioneering environmental technologies and through the widespread avoidance of fossil fuels, we are fulfilling our ecological responsibility.

We continuously invest in measures to protect our climate. Sustainability and innovation are key factors in our company's success.

The following projects have already been implemented successfully:

- Company-wide lighting has been replaced with energy-saving LED lighting to increase energy efficiency and reduce electricity consumption.

- With the gradual replacement of our fleet of side loader forklifts with electric forklifts, as well as an electric charging station and the increased use of electric vehicles for short and medium-length journeys, we are creating the optimum conditions for climate-friendly and future-oriented electromobility.

- In the Perwarth plant, a new, energy-saving biomass combustion system with electric filter has been built for supplying process heat. The discharge of air pollutants is prevented as far as possible with the electric filter. The CO2 saving as a result of the new heating system amounts to roughly 740,000 kg per year.

- In recent years, we have built high-performance, energy-efficient systems for wood drying, which are equipped with systems for heat recovery. This means that heat requirements for wood drying can be reduced by 50% and electricity consumption is being scaled back considerably.